Empowering Manufacturing Businesses with IoT Technologies

In this edition of GBX Tech Insights, we delve into the realm of IoT technologies and their indispensable role in transforming manufacturing businesses. As clients demand increased customizations and faster production, manufacturers face the challenge of boosting productivity while maintaining a competitive edge. IoT offers a game-changing solution, allowing businesses to optimize operations, digitize supply chains, and create smart factories.

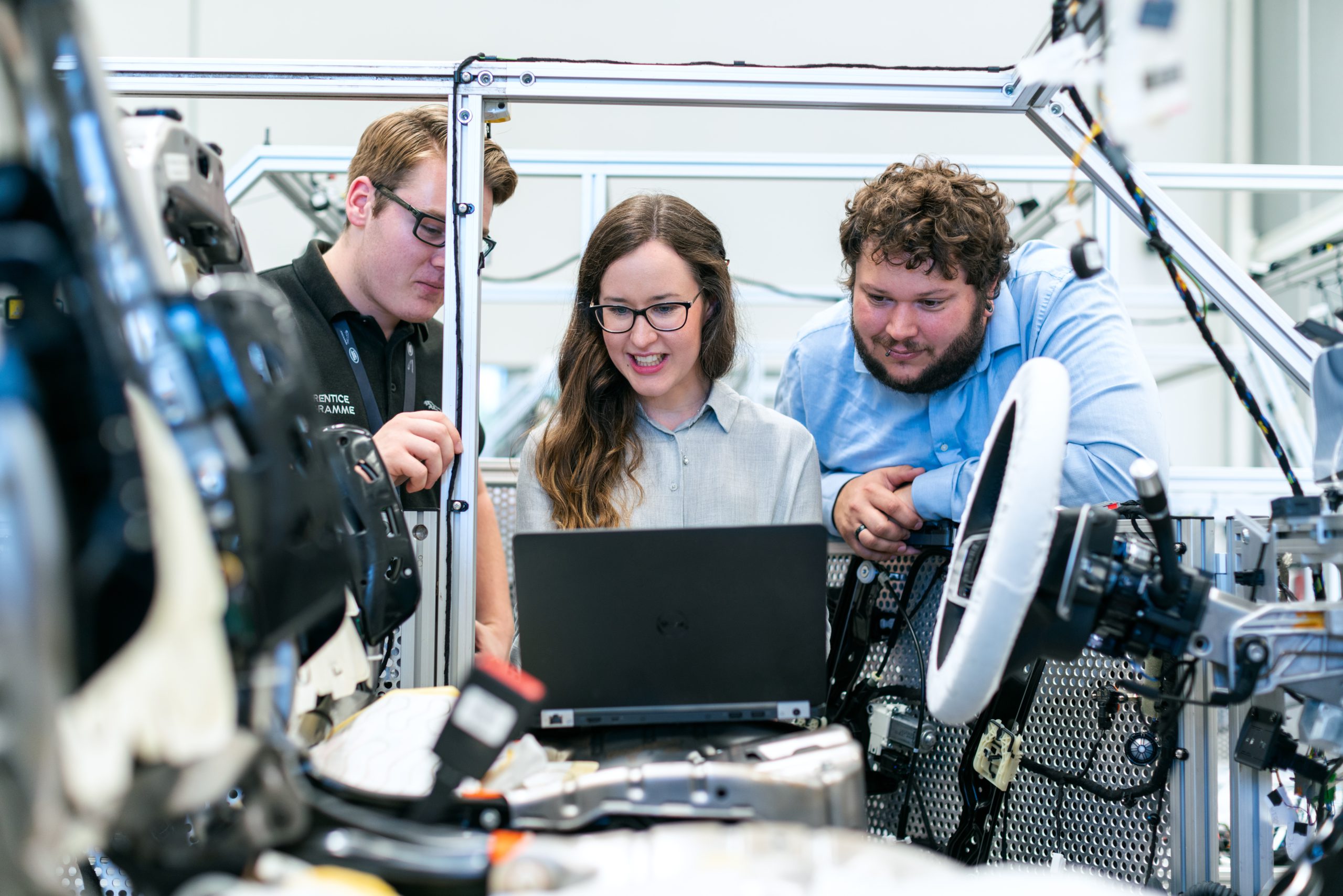

Automating Production for Unparalleled Efficiency

IoT devices revolutionize manufacturing by collecting performance data automatically. This data is a goldmine for predictive maintenance, ensuring minimal downtime and increased machine availability. Manufacturers can liberate their workforce from repetitive tasks and empower them with more creative, engineering-focused roles. As IoT streamlines processes, companies can develop innovative products and business models based on the invaluable data they generate.

Digitizing the Supply Chain for Enhanced Transparency

With IoT, tracking products in real-time becomes a reality, eliminating human error in records. Transport assets are utilized efficiently, and the most optimized routes are calculated, minimizing costs. Enhanced data sharing between stakeholders fosters transparency and automation, leading to greater cost efficiencies.

Logistics Bridge: A Seamless Track and Trace Solution

Our Logistics Bridge simplifies track-and-trace technologies, reducing operational costs, and enhancing transparency. The solution is particularly vital for shipping sensitive goods requiring temperature control. IoT-driven sensors ensure a smoother supply chain, empowering businesses to thrive in an increasingly competitive market.

Smart Factories: Meeting Demand and Sustainability

IoT-powered smart sensors and chips revolutionize the modern factory, providing valuable insights into machinery, materials, and output readiness. Manufacturers can meet demands for shorter delivery times and environmentally sustainable operations. Customization reaches new heights, with lot sizes as small as one unit, while protecting profit margins.

Proactive Asset Management for Optimal Efficiency

Smart sensors and software create digital twins, virtual representations of machinery, enabling remote monitoring and predictive maintenance. With the aid of machine learning, manufacturers can anticipate breakdowns, reduce on-site visits, and enhance production schedules. Maintenance becomes proactive, and unplanned downtime is a thing of the past.

Augmented Reality: Efficiency and Safety Combined

Augmented reality glasses optimize worker efficiency and safety. On assembly lines, smart glasses display packing instructions, eliminating the need for clipboards. Voice and gesture controls streamline operations, while location tracking alerts employees of potential risks. A safer and more efficient workplace is within reach with IoT-driven innovations.

Integrating IoT Into Your Business: A Holistic Approach

NTT DATA Business Solutions ensures seamless integration of IoT data with ERP platforms like SAP S/4HANA and next-generation CRMs. Our expertise in IoT and comprehensive solutions enable organizations to access and analyze data effectively, empowering them to stay ahead in the IoT-driven future.

It’s time to embrace the IoT technologies of today, unlock unprecedented efficiency, and secure your position as an industry leader. Let GBX TECHNOLOGY be your trusted partner in this transformative journey. Reach out to us and experience the limitless possibilities of IoT for your manufacturing business.

Learn more about GBX TECHNOLOGY and our IoT solutions at www.gbxtechnology.net

To read and subscribe to our weekly Newsletter “GBX Tech Insights”, click here.